HWP High-Wind Purlin Hanger

Top-Flange Hangers for Plated Truss

This product's information may differ depending on the category of use. You are currently viewing details related to Top-Flange Hangers for Plated Truss. You can also view product information related to the categories of: Top-Flange Hangers for Solid Sawn Lumber, Top-Flange Hangers for Engineered Wood

Product Details

The HWP is designed to support joists on purlins or beams in both wood and cold-formed steel construction. This top-flange hanger has enhanced uplift and is ideal for high-wind applications. The HWP offers design flexibility and versatility in supporting trusses off of wood or steel and can have a sloped and/or skewed seat up to 45°.

Key Features

- Modifiable with alteration options including opened/closed top-flange and offset top-flange

- Top flange may be sloped to a maximum of 35° to accommodate a sloped header

- Features a solid one-piece top flange that provides extra stability in panelized roof applications

Material

- 7-gauge top flange and 12-gauge stirrup

Finish

- Simpson Strong-Tie gray paint. Hot-dip galvanized available.

Installation

- Use all specified fasteners.

- H dimensions are sized to account for normal joist shrinkage. W dimensions are for dressed timber widths.

- The HWP may be used for weld-on applications. The minimum-size weld is a 1 1/2"-long fillet weld to each side of the top flange; weld size to match hanger material thickness. See General Instructions for the Installer, note k for weld information. Weld-on applications have the maximum allowable capacity listed. Uplift loads do not apply to this application. For additional load information, refer to technical bulletin Top-Flange Hangers Welded to Structural Steel Members (T-C-WELDUPLFT).

- Hangers can support multi-ply carried members; the individual members must be secured together to work as a single unit before installation into the hanger.

- Non-modified hangers can support joists sloped up to 1/4:12 using table loads. For joists sloping between 1/4:12 and 3/4:12 use 85% of the table loads. See technical bulletin Sloped Joist in Non-Sloped Hangers (T-C-SLOPEJST).

- If joist is shorter than hanger by more than 1/2" use only 50% of the table loads.

- Web stiffeners are required for these hangers when using engineered wood.

- For attaching to multi-ply headers in engineered wood applications, refer to technical bulletin Top-Flange Hanger Reductions for Multiple-Ply Headers (T-C-MPLYHEADR).

Options

- See General Notes for Hanger Options.

- Some model configurations may differ from those shown. Contact Simpson Strong-Tie for details.

- Hangers with a skew greater than 15° may have all the joist nails on the outside angle.

- For skewed condition, top flange width can increase up to 18". Contact Simpson Strong-Tie for specific application.

- When using in solid sawn or engineered wood applications, specify the slope up or down in degrees from the horizontal plane and/or the skew right or left in degrees from the perpendicular vertical plane. Specify whether low side, high side or center of joist will be flush with the top of the header.

- The HWP may have a sloped and/or skewed seat up to 45°. See Modifications and Associated Load Reductions table below for reduction associated with modifications.

- The top flange of the HWP may be offset and/or sloped down up to 35°. The top flange may also be opened/closed up to 30°. See Modifications and Associated Load Reductions table below.

- Hangers with a skew greater than 15° may have all the joist nails on the outside angle.

- For hanger modification options, see Modifications and Associated Load Reductions table below.

- For concrete and masonry applications, refer to the WMU top-flange hanger.

Related Literature

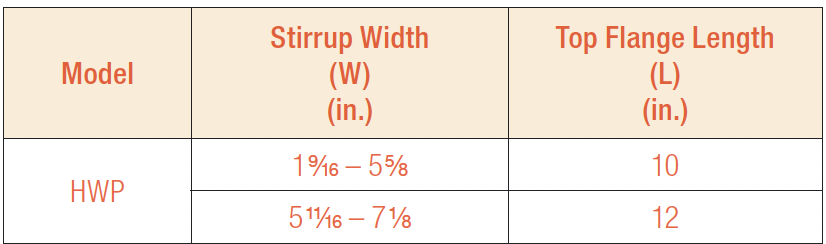

Product Information Table

Load Tables

- Top-Flange Hangers – Solid Sawn Lumber (DF / SP) Tables

- Top-Flange Hangers – Solid Sawn Lumber (SPF / HF) Tables

- Top-Flange Hangers – I-Joists, Glulam and SCL Tables

See Hanger Options for hanger modifications, which may result in reduced loads.

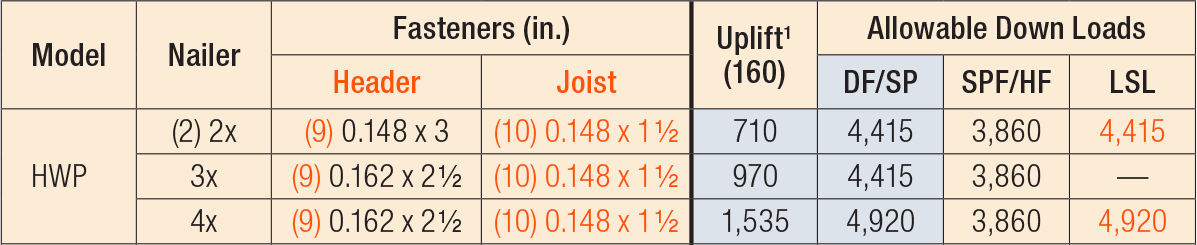

The table indicates the maximum allowable loads for HWP hangers used on wood nailers. Nailers are wood members attached to the top of a steel I-beam, concrete or masonry wall.

Nailer Table

- Attachment of nailer to supporting member is the responsibility of the designer.

- Uplift loads are based on DF/SP lumber. For SPF/HF, use 0.86 x DF/SP uplift load.

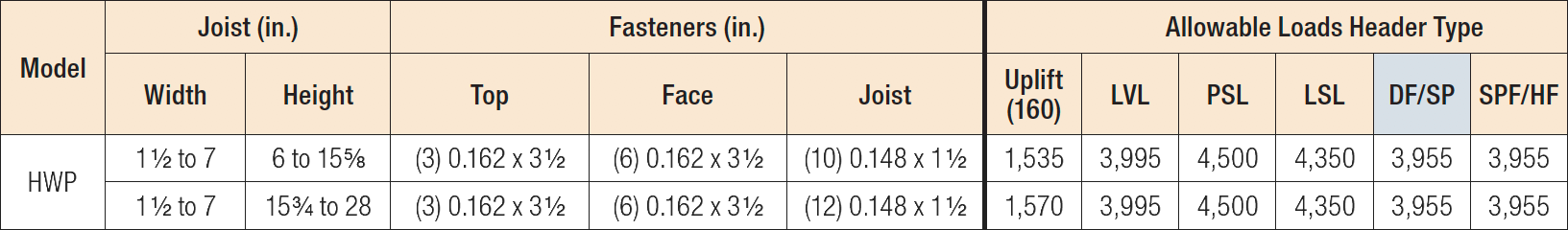

Various Header Applications

- Code values are based on DF/SP header species.

- Uplift loads have been increased for wind or earthquake loading with no further increase allowed. Reduce where other loads govern.

- For hanger heights exceeding the joist height, the allowable load is 0.50 of the table load.

- Fasteners: Nail dimensions in the table are listed diameter by length. For additional information, see Fastener Types and Sizes Specified for Simpson Strong-Tie Connector.

Modifications and Associated Load Reductions for HWP

| Models | Seat | Top Flange | Top Flange and Seat | Joist Height | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Seat Sloped 45° Max. | Seat Skewed Type A | Seat Skewed Type B | Seat Sloped and Skewed Type A 1°-45° | Top Flange Sloped 35° Max. | Top Flange Bent Open or Closed 30° Max. | Top Flange Offset | Top Flange Offset and Skewed Seat Type A, Bevel Cut 1°-45° | Top Flange Offset and Skewed Seat Type B, Plumb Cut 1°-84° | Joist Shorter Than Hanger | |||||||

| Slope Up | Slope Down | 1°-45° | 1°-45° | 46°-84° | Up | Down | Narrow | Wide | Narrow | Wide | Narrow | Wide | ||||

|

Footnotes

|

||||||||||||||||

| HWP | 1.0 | 0.8 | 1.0 | N/A | 1.0 | 0.8 | (90-a)/90 | (90-a)/90 | 0.5 | 0.6 | 0.5 | 0.6 | N/A | By more than 1/2", 0.50. By 1/2" or less, 1.00. | ||

Reduction Factor Instructions

Allowable Download =

(lowest of Seat, Top Flange, or Joist Height) x (Table Load).

Allowable Uplift =

as noted in table per height, see table above.

HWP Top View

Skewed Left Type A Hanger

(bevel-cut joist shown)

Typical HWP Top Flange

Sloped Down Left with Low Side Flush

Typical HWP sloped down, skewed right with type A hanger (joist end must be bevel cut).

When ordering, specify low side flush, center flush or high side flush.

Code Reports & Compliance

Drawings

| DWG | DXF | RFA | IFC | SAT | |||

|---|---|---|---|---|---|---|---|