Deck-Drive™ DCU COMPOSITE Screw (Collated)

Product Details

The Deck-Drive DCU Composite screw is engineered to provide beautiful fastening results for all types of composite decking while also offering greater ease of installation, a clean finish and superb corrosion resistance. The Deck-Drive DCU is the go-to-screw for all your composite decking applications, eliminating the need to mix and match screws to the decking.

Deck-Drive DCU Composite decking screws are available in carbon steel with our Quik Guard® coating. For superior corrosion resistance in marine or high-exposure environments, choose the appropriate stainless-steel DCU screw (Type 305 or Type 316). DCU screws provide a clean finish because of their special head design and are available in a wide range of colors, matched to blend with most major decking manufacturers.

Key Features

- Available in carbon steel, as well as Type 305 and Type 316 stainless steel for high to severe levels of corrosion resistance

- Tri-lobe thread design reduces damage to the composite board while driving

- Inverted upper threads clear excess material to ensure that the screw has a clean finish

- Unique cut point penetrates composite decking with ease for fast starts

- Cap-head prevents mushrooming and material from rising up above the deck for a smoother, clean-looking installation

- Approved fastener (by Trex®) for Trex composite decking

- 6-lobe drive recess for secure driving

- When countersinking for DCU plug solutions, use the Quik Drive® Auto-Set Driver™ Bit (model QRTX20-PL) with depth set to maximum

Applications

- Fastening composite decking boards

Related Links

- Fastening Systems Technical and Installation Notes

- Composite-Decking Color Cross-Reference – match Simpson-Strong Tie screw colors to your decking material

- Deck-Drive DCU Composite Screw also available in bulk for hand-drive fastening

Catalog Pages

- Fastener Product Information: C-F-2023 (Fastening Systems), pages 226–227

- Fastener Technical Data and Loads: C-F-2023TECHSUP, page 156

Related Literature

Product Information Table

| Model No. | Coating/Material | Screw Size | Length (in.) | Head Diameter (in.) | Drive Type | Head Type | Thread Type | Point Type | Color | Compatible Tools | Packaging Qty. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| DCU234SBR01 | Quik Guard® Coating | #10 | 2 3/4 | 0.230 | T20 6-Lobe | Cap Head | Tri-Lobe Threads | Type-17 Point | Brown 01 | Quik Drive® PRO300SG2 | 1000 |

| DCU234SBR05 | Quik Guard® Coating | #10 | 2 3/4 | 0.230 | T20 6-Lobe | Cap Head | Tri-Lobe Threads | Type-17 Point | Brown 05 | Quik Drive® PRO300SG2 | 1000 |

| DCU234SGR | Quik Guard® Coating | #10 | 2 3/4 | 0.230 | T20 6-Lobe | Cap Head | Tri-Lobe Threads | Type-17 Point | Gray | Quik Drive® PRO300SG2 | 1000 |

| DCU234SGR01 | Quik Guard® Coating | #10 | 2 3/4 | 0.230 | T20 6-Lobe | Cap Head | Tri-Lobe Threads | Type-17 Point | Gray 01 | Quik Drive® PRO300SG2 | 1000 |

| DCU234SGR04 | Quik Guard® Coating | #10 | 2 3/4 | 0.230 | T20 6-Lobe | Cap Head | Tri-Lobe Threads | Type-17 Point | Gray 04 | Quik Drive® PRO300SG2 | 1000 |

| DCU234SRD | Quik Guard® Coating | #10 | 2 3/4 | 0.230 | T20 6-Lobe | Cap Head | Tri-Lobe Threads | Type-17 Point | Red | Quik Drive® PRO300SG2 | 1000 |

| DCU234SRD01 | Quik Guard® Coating | #10 | 2 3/4 | 0.230 | T20 6-Lobe | Cap Head | Tri-Lobe Threads | Type-17 Point | Red 01 | Quik Drive® PRO300SG2 | 1000 |

| DCU234STN | Quik Guard® Coating | #10 | 2 3/4 | 0.230 | T20 6-Lobe | Cap Head | Tri-Lobe Threads | Type-17 Point | Tan | Quik Drive® PRO300SG2 | 1000 |

| DCU234STN01 | Quik Guard® Coating | #10 | 2 3/4 | 0.230 | T20 6-Lobe | Cap Head | Tri-Lobe Threads | Type-17 Point | Tan 01 | Quik Drive® PRO300SG2 | 1000 |

| DCU234STN02 | Quik Guard® Coating | #10 | 2 3/4 | 0.230 | T20 6-Lobe | Cap Head | Tri-Lobe Threads | Type-17 Point | Tan 02 | Quik Drive® PRO300SG2 | 1000 |

| DCU234STN03 | Quik Guard® Coating | #10 | 2 3/4 | 0.230 | T20 6-Lobe | Cap Head | Tri-Lobe Threads | Type-17 Point | Tan 03 | Quik Drive® PRO300SG2 | 1000 |

| DCU234S305 | Type 305 Stainless Steel | #10 | 2 3/4 | 0.230 | T20 6-Lobe | Cap Head | Tri-Lobe Threads | Type-17 Point | None | Quik Drive® PRO300SG2 | 1000 |

| DCU234S316 | Type 316 Stainless Steel | #10 | 2 3/4 | 0.230 | T20 6-Lobe | Cap Head | Tri-Lobe Threads | Type-17 Point | None | Quik Drive® PRO300SG2 | 1000 |

| DCU234S316BR01 | Type 316 Stainless Steel | #10 | 2 3/4 | 0.230 | T20 6-Lobe | Cap Head | Tri-Lobe Threads | Type-17 Point | Brown 01 | Quik Drive® PRO300SG2 | 1000 |

| DCU234S316BR05 | Type 316 Stainless Steel | #10 | 2 3/4 | 0.230 | T20 6-Lobe | Cap Head | Tri-Lobe Threads | Type-17 Point | Brown 05 | Quik Drive® PRO300SG2 | 1000 |

| DCU234S316GR | Type 316 Stainless Steel | #10 | 2 3/4 | 0.230 | T20 6-Lobe | Cap Head | Tri-Lobe Threads | Type-17 Point | Gray | Quik Drive® PRO300SG2 | 1000 |

| DCU234S316GR01 | Type 316 Stainless Steel | #10 | 2 3/4 | 0.230 | T20 6-Lobe | Cap Head | Tri-Lobe Threads | Type-17 Point | Gray 01 | Quik Drive® PRO300SG2 | 1000 |

| DCU234S316GR04 | Type 316 Stainless Steel | #10 | 2 3/4 | 0.230 | T20 6-Lobe | Cap Head | Tri-Lobe Threads | Type-17 Point | Gray 04 | Quik Drive® PRO300SG2 | 1000 |

| DCU234S316GR05 | Type 316 Stainless Steel | #10 | 2 3/4 | 0.230 | T20 6-Lobe | Cap Head | Tri-Lobe Threads | Type-17 Point | Gray 05 | Quik Drive® PRO300SG2 | 1000 |

| DCU234S316RD | Type 316 Stainless Steel | #10 | 2 3/4 | 0.230 | T20 6-Lobe | Cap Head | Tri-Lobe Threads | Type-17 Point | Red | Quik Drive® PRO300SG2 | 1000 |

| DCU234S316RD01 | Type 316 Stainless Steel | #10 | 2 3/4 | 0.230 | T20 6-Lobe | Cap Head | Tri-Lobe Threads | Type-17 Point | Red 01 | Quik Drive® PRO300SG2 | 1000 |

| DCU234S316TN | Type 316 Stainless Steel | #10 | 2 3/4 | 0.230 | T20 6-Lobe | Cap Head | Tri-Lobe Threads | Type-17 Point | Tan | Quik Drive® PRO300SG2 | 1000 |

| DCU234S316TN01 | Type 316 Stainless Steel | #10 | 2 3/4 | 0.230 | T20 6-Lobe | Cap Head | Tri-Lobe Threads | Type-17 Point | Tan 01 | Quik Drive® PRO300SG2 | 1000 |

| DCU234S316TN02 | Type 316 Stainless Steel | #10 | 2 3/4 | 0.230 | T20 6-Lobe | Cap Head | Tri-Lobe Threads | Type-17 Point | Tan 02 | Quik Drive® PRO300SG2 | 1000 |

| DCU234S316TN03 | Type 316 Stainless Steel | #10 | 2 3/4 | 0.230 | T20 6-Lobe | Cap Head | Tri-Lobe Threads | Type-17 Point | Tan 03 | Quik Drive® PRO300SG2 | 1000 |

| DCU234S316TN05 | Type 316 Stainless Steel | #10 | 2 3/4 | 0.230 | T20 6-Lobe | Cap Head | Tri-Lobe Threads | Type-17 Point | Tan 05 | Quik Drive® PRO300SG2 | 1000 |

Load Tables

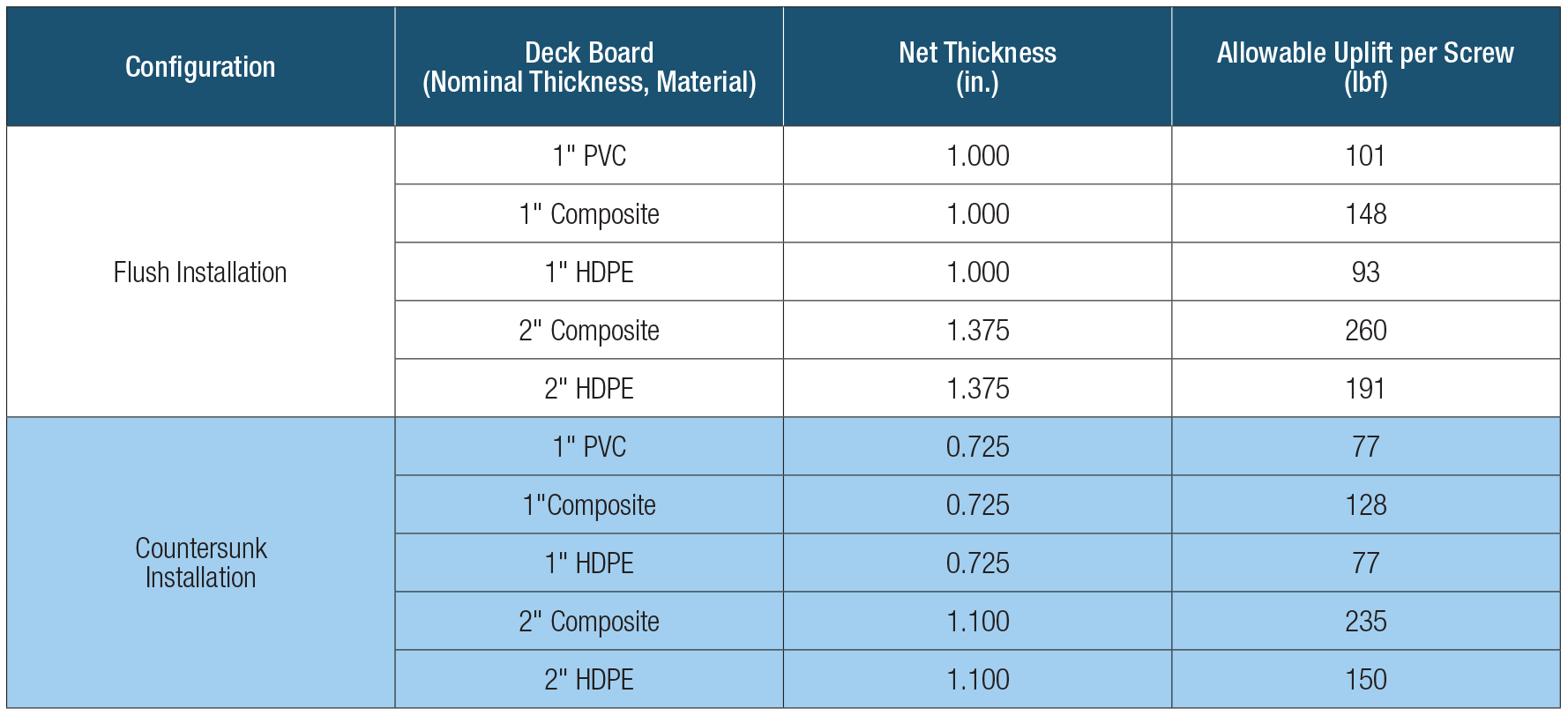

DCU COMPOSITE Screw — Allowable Uplift for PVC, Composite, and HDPE Deck Boards Fastened to Southern Pine Framing

- Allowable uplift is limited by fastener pull-through value, which is the lessor of fastener pull-through and withdrawal. No other properties of the deck materials or deck construction are considered.

- Withdrawal property is based on duration of load of CD = 1.6 and wet service factor of CM = 0.7.

Code Reports & Compliance

Drawings

| DWG | DXF | RFA | IFC | SAT | |||

|---|---|---|---|---|---|---|---|