THASR/THASL Adjustable/Skewable Truss Hangers

Product Details

The THASR/L is designed to support trusses and beams. This versatile U-shaped hanger combines the height adjustability of the THA with field adjustability. These key features provide maximum flexibility for the installer. Shipped at 22 1/2° right or left, the THASR/L hangers can be field-skewed from 22 1/2° to 75°.

Key Features

- Eliminates the need for special orders

- The THASR/L29, 29-2 and 422 are replacing the former 218, 218-2 and 418 versions

- The THASR/L single- and two-ply versions have straps 9" tall; the 4x version has 22" straps to fit more parallel-chord truss applications

- The versions have only one acute side bend line to ease design and installation

- Joist fasteners are only required from one side for skews greater than 22 1/2°

- Rated for installation with either nails or Strong-Drive® SD Connector screws

Material

- 16 gauge

Finish

- Galvanized. Some products available in ZMAX® coating. See Corrosion Information.

Installation

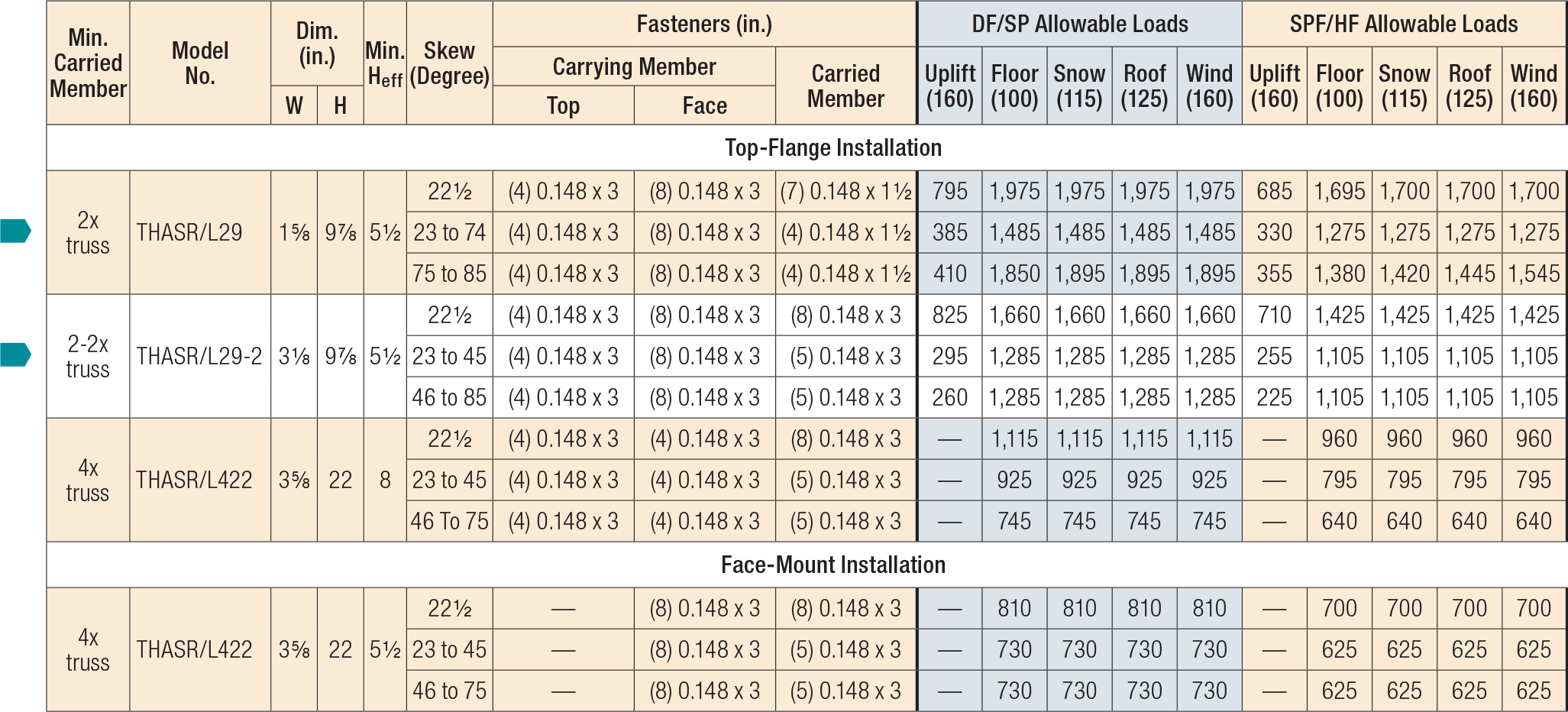

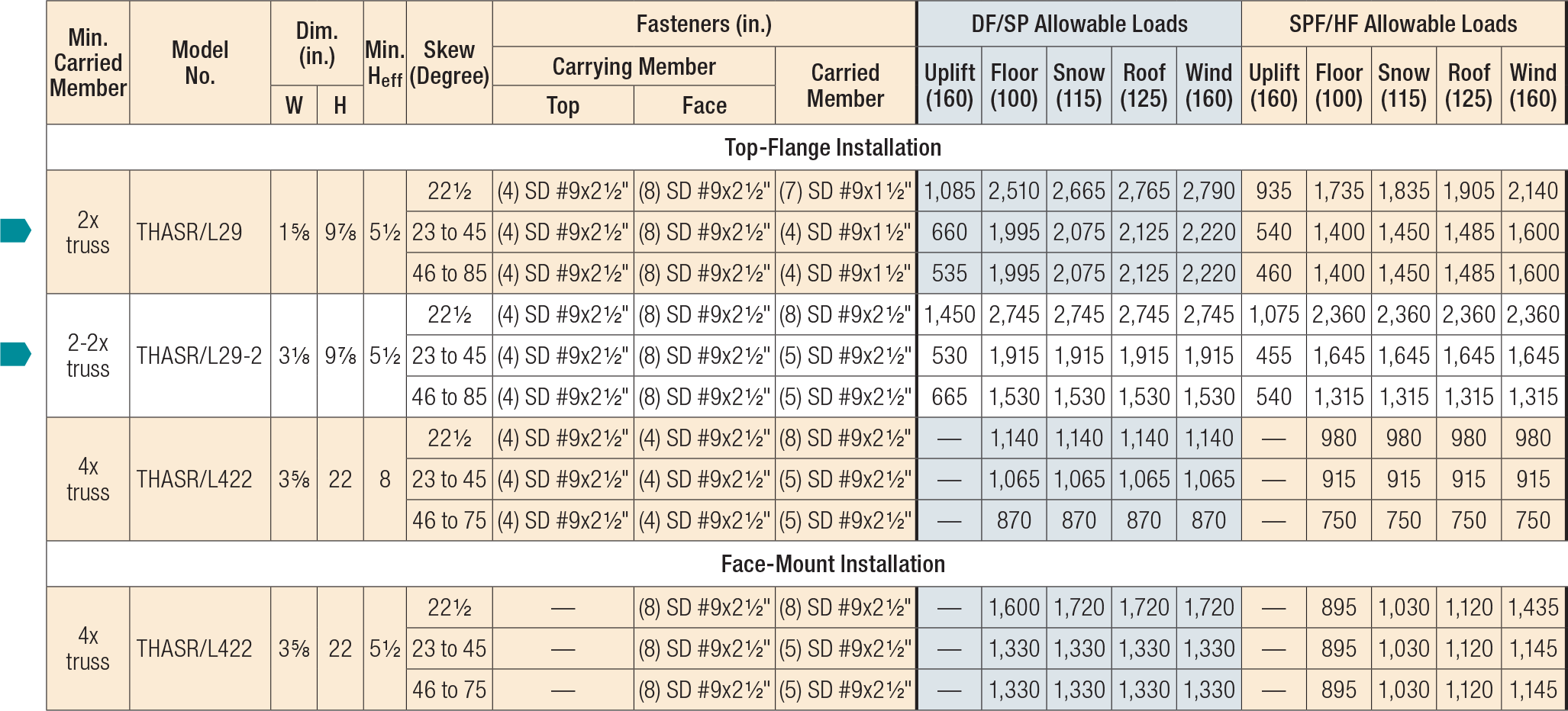

- Use all specified fasteners; see General Notes and the table below.

- Product is factory-skewed to 22 1/2° and may be field-skewed from 22 1/2° to 75° (up to 85° for the THASR/L29 and THASR/L29-2). See Installation Sequence in the image gallery for skews greater than 22 1/2°.

- For top-flange installations, the straps must be field-formed over the header a minimum of 2".

- THASR/L29 and THASR/L29-2 — for installations where either strap cannot be field-formed over the header, install the strap(s) vertically and fill all holes. Loads must be reduced as noted in the table footnotes.

- THASR/L422 — for face-mount installations, install the carrying member fasteners into the lowest holes.

Related Literature

Product Information Table

| Model No. | Skew L/R | Ga. | W (in.) | H (in.) | Coating/Material | Packaging Qty. |

|---|---|---|---|---|---|---|

| THASL29 | Left | 16 | 1 5/8 | 9 7/8 | Zinc Galvanized, G90 | 1 |

| THASL29-2 | Left | 16 | 3 1/8 | 9 7/8 | Zinc Galvanized, G90 | 1 |

| THASL29-2Z | Left | 16 | 3 1/8 | 9 7/8 | ZMAX® | 1 |

| THASL29Z | Left | 16 | 1 5/8 | 9 7/8 | ZMAX® | 1 |

| THASL422 | Left | 16 | 3 5/8 | 22 | Zinc Galvanized, G90 | 1 |

| THASR29 | Right | 16 | 1 5/8 | 9 7/8 | Zinc Galvanized, G90 | 1 |

| THASR29-2 | Right | 16 | 3 1/8 | 9 7/8 | Zinc Galvanized, G90 | 1 |

| THASR29-2Z | Right | 16 | 3 1/8 | 9 7/8 | ZMAX® | 1 |

| THASR29Z | Right | 16 | 1 5/8 | 9 7/8 | ZMAX® | 1 |

| THASR422 | Right | 16 | 3 5/8 | 22 | Zinc Galvanized, G90 | 1 |

Load Tables

These products are available with additional corrosion protection. Additional products on this page may also be available with this option, check with Simpson Strong-Tie for details.

Many of these products are approved for installation with Strong-Drive® SD Connector screws.

Allowable Loads for Installation with Nails

Allowable Loads for Installation with Strong-Drive® SD Connector screws

- Uplift loads have been increased for earthquake or wind loading with no further increase allowed. Reduce where other loads govern.

- Wind (160) is a download rating.

- Minimum carried member heel height shall be 4 1/2".

- Heff is the distance from the top of the hanger seat to the top of the carrying member.

- For tabulated top-flange installation loads, the straps must be wrapped over the header a minimum of 2". Allowable downloads for the THASR/L29 and THASR/L29-2 with one or both straps installed vertically (all holes filled) are 90% of the tabulated downloads for skews greater than 22 1/2° and 85% of the tabulated downloads for 22 1/2° skews. Allowable uplift capacities are 100% of the tabulated uplift load capacities.

- Allowable downloads for 75°–85° skews with one or both straps installed vertically (with all holes filled) shall be limited to 75% of these loads.

- Fasteners: Nail dimensions in the table are listed diameter by length. SD screws are Simpson Strong-Tie® Strong-Drive SD Connector screws. For additional information, see Fastener Types and Sizes Specified for Simpson Strong-Tie Connectors.

Code Reports & Compliance

Drawings

| DWG | DXF | RFA | IFC | SAT | |||

|---|---|---|---|---|---|---|---|