THJM Multiple-Truss Hip/Jack Hanger

Product Details

The THJM is a non-welded hanger designed to carry radial-end jack framing and provide optimal efficiency for those multi-plane, angled bay roofs over breakfast, study and library alcoves. The unique patented design of the THJM accommodates 2x4 girder bottom chords and uses our Strong-Drive® SDS Heavy-Duty Connector screws for easy installation with minimal fasteners.

Key Features

- The THJM hangers are designed for installation with 1/4" x 3" Strong-Drive SDS Heavy-Duty Connector screws that are included with the parts.

- The THJM2-4-SDS3 is designed for four incoming jack trusses with the outer jacks being 22 1/2° from the face of the girder and the inner jacks being 45° from each other and the outer jacks.

- The THJM2-5-SDS3 is designed for five jacks coming into the hanger at 30° from the girder and each other.

- Tabs on the seats of the THJM assist in the placement of the jacks and also include obround holes for optional slant nails (0.148" x 1 1/2") when increased uplift is required.

Material

- 12 gauge

Finish

- Galvanized

Installation

- Use all specified fasteners; see General Notes

- Each carried jack truss requires one 1/4" x 3" Strong-Drive SDS Heavy-Duty Connector screw installed into the bottom chord through the bottom of the hanger seat

- For installation on girders with 2x6 or 2x8 bottom chords, install one additional 1/4" x 3" Strong-Drive SDS Heavy-Duty Connector screw in the triangular hole on each vertical strap

- Install two 0.148" x 1 1/2" slant nails in the obround holes on each of the seat tabs to achieve the additional uplift load noted in the table footnotes

Patent Information

- US Patent 8,443,569

- Canadian Patent 2,719,864

Related Literature

Product Information Table

| Model No. | Member Size | Ga. | Coating/Material | Packaging Qty. |

|---|---|---|---|---|

| THJM2-4-SDS3 | (4) single 2x jack trusses or joists | 12 | Zinc Galvanized, G90 | 1 |

| THJM2-5-SDS3 | (5) single 2x jack trusses or joists | 12 | Zinc Galvanized, G90 | 1 |

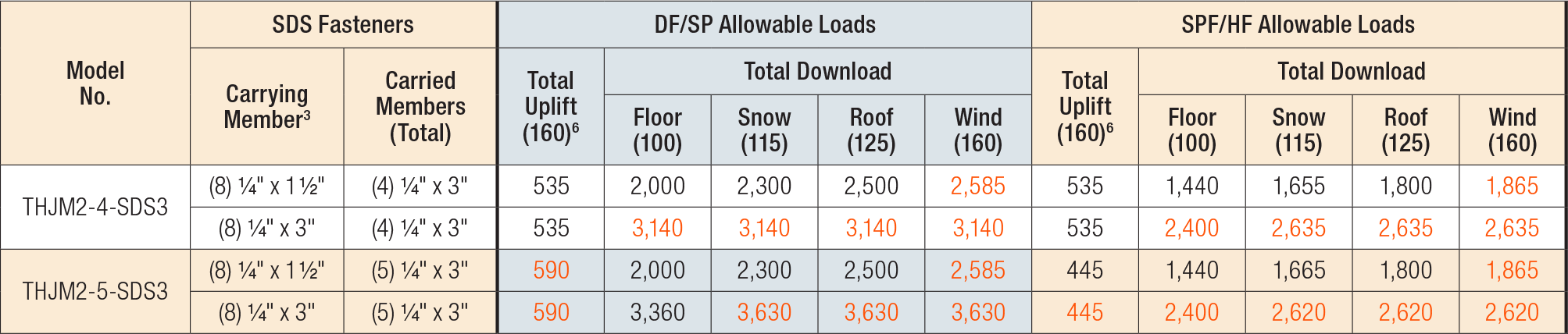

Load Tables

- Tabulated loads are the total allowable loads of all carried members combined; the load on any single carried member shall not exceed 25% of the total published load for the THJM2-4 or 20% of the total published load for the THJM2-5.

- Uplift loads have been increased for earthquake or wind loading with no further increase allowed. Reduce where other loads govern.

- A minimum two-ply carrying member is required for the 1/4" x 3" Strong-Drive® SDS Heavy-Duty Connector screws (provided). For single 2x carrying members, use 1/4" x 1 1/2" SDS screws (sold separately) with corresponding loads.

- Truss chord cross-grain tension may limit allowable loads per ANSI/TPI 1-2014. The optional triangle holes may be used for installation on 2x6 and larger carrying members, for a total of 10 fasteners into the carrying member, to resist cross-grain tension forces when no other mechanical reinforcement is available.

- Tabs on the seats of the THJM hangers have obround holes for optional 0.148" x 1 1/2" slant nails (two per carried member) when additional uplift load is required. Total allowable uplift with the optional 0.148" x 1 1/2" slant nailing is 760 lb. (DF/SP/SPF/HF).

- Strong-Drive SDS Heavy-Duty Connector screws may be installed through metal truss plates as approved by the truss designer, provided the requirements of ANSI/TPI 1-2014, Sections 7.5.3.4 and 8.9.2 are met (predrilling required through the plate using a 5/32" bit maximum).

Code Reports & Compliance

Drawings

| DWG | DXF | RFA | IFC | SAT | |||

|---|---|---|---|---|---|---|---|