HHETA Extra-Heavy Embedded Truss Anchor

Lateral Load Transfer - Masonry

This product's information may differ depending on the category of use. You are currently viewing details related to Lateral Load Transfer - Masonry. You can also view product information related to the categories of: Girder Tiedowns for Masonry, Truss-to-Wall Connections, Girder Tiedowns for Plated Truss, Roof Truss and Rafter Connectors, Ties, and Straps for Cold-Formed Steel Construction

Product Details

The HHETA provides an engineered method to attach roof trusses securely to concrete and masonry walls. This extra-heavy embedded truss anchor features staggered nail patterns to strengthen uplift resistance and can be used in pairs on single- and multi-ply trusses. The versatile HHETA can be installed straight or field-bent around truss or rafter members.

Key Features

- Indented embedment line ensures accurate embedment depth

- Compatible with the Simpson Strong-Tie TSS and TBP8 moisture barrier plate

- Load rated for wind and seismic forces

Material

- 14 gauge

Finish

- Galvanized

Installation

- Use all specified fasteners; see General Notes.

- Embedded 4" into a 6" min. concrete beam or 8" nominal grouted block wall.

- For mislocated truss anchors which are greater than 1/8" but less than 1 1/2" from the face of the truss, a shim must be provided. Shim design by truss engineer. When gap is greater than 1 1/2", abandon existing embedded truss anchor and install new anchor per designer.

- Minimum spacing of single anchors is twice the embedment depth for full load. For closer spacing, see loads for double anchor installation.

- In double anchor installations, install anchors with spoons facing outward and straps spaced no more than 1/8" wider than the rafter/truss width. Do not install nails where the straps overlap when wrapped over the rafter/truss.

- Straps do not need to be wrapped over the rafter/truss to achieve tabulated loads, unless noted otherwise.

Related Literature

Product Information Table

| Model No. | Ga. | H (in.) | Coating/Material | Packaging Qty. |

|---|---|---|---|---|

| HHETA16 | 14 | 12 | Zinc Galvanized, G90 | 1 |

| HHETA18 | 14 | 14 | Zinc Galvanized, G90 | 1 |

| HHETA20 | 14 | 16 | Zinc Galvanized, G90 | 1 |

| HHETA24 | 14 | 20 | Zinc Galvanized, G90 | 1 |

| HHETA40 | 14 | 36 | Zinc Galvanized, G90 | 1 |

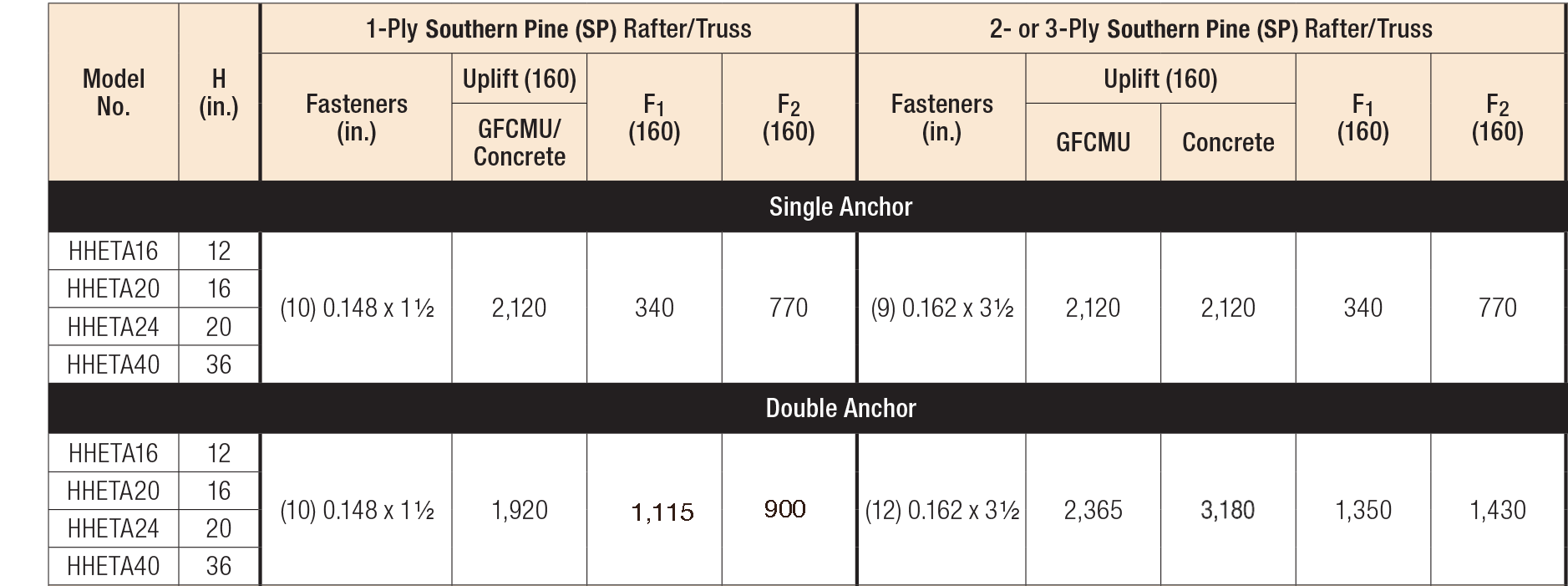

Load Tables

- Loads have been increased for wind or earthquake loading, with no further increase allowed. Reduce where other loads govern.

- Concrete shall have a minimum compressive strength of f'c = 2,500 psi.

- Grout-filled CMU (GFCMU) shall have a minimum compressive strength of f'm = 2,000 psi.

- For simultaneous loads in more than one direction, the connector must be evaluated using either the Unity Equation or the 75% Rule, as described in Straps and Ties General Notes.

- The HHETA allowable F1 load can be increased to 435 lb. if the strap is wrapped over the truss and a minimum of 12 nails are installed.

- F1 lateral loads listed for double HHETA on 2- or 3-ply rafter/truss may cause an additional 1/16" deflection beyond the standard 1/8" limit where the straps are installed not wrapped over the heel as shown.

- Minimum edge distance for HHETA is 1 1/2" for concrete and 2" for masonry. Where edge distance is less than 2" for masonry, the maximum uplift load is 1,005 lb.

- It is acceptable to use a reduced number of fasteners provided that there is a reduction in uplift allowable load. Calculate the connector allowable load for a reduced number of nails as follows: Allowable Load = (No. of Nails Used) / (No. of Nails in Table) x Table Load. Lateral loads require the lowest 7 nail holes filled for HHETA.

- For double HHETA installations, install half of the required fasteners in each strap.

- Fasteners: Nail dimensions in the table are listed diameter by length. For additional information, see Fastener Types and Sizes Specified for Simpson Strong-Tie Connectors.

Code Reports & Compliance

Drawings

| DWG | DXF | RFA | IFC | SAT | |||

|---|---|---|---|---|---|---|---|