HHETA Extra-Heavy Embedded Truss Anchor

Girder Tiedowns for Masonry

This product's information may differ depending on the category of use. You are currently viewing details related to Girder Tiedowns for Masonry. You can also view product information related to the categories of: Lateral Load Transfer - Masonry, Truss-to-Wall Connections, Girder Tiedowns for Plated Truss, Roof Truss and Rafter Connectors, Ties, and Straps for Cold-Formed Steel Construction

Product Details

The HHETA provides an engineered method to attach roof trusses securely to concrete and masonry walls. This extra-heavy embedded truss anchor features staggered nail patterns to strengthen uplift resistance and can be used in pairs on single- and multi-ply trusses. The versatile HHETA can be installed straight or field-bent around truss or rafter members.

Key Features

- Indented embedment line ensures accurate embedment depth

- Compatible with the Simpson Strong-Tie TSS and TBP8 moisture barrier plate

- Load rated for wind and seismic forces

Material

- 14 gauge

Finish

- Galvanized

Installation

- Use all specified fasteners; see General Notes.

- Embedded 4" into a 6" min. concrete beam or 8" nominal grouted block wall.

- For mislocated truss anchors which are greater than 1/8" but less than 1 1/2" from the face of the truss, a shim must be provided. Shim design by truss engineer. When gap is greater than 1 1/2", abandon existing embedded truss anchor and install new anchor per designer.

- Minimum spacing of single anchors is twice the embedment depth for full load. For closer spacing, see loads for double anchor installation.

- In double anchor installations, install anchors with spoons facing outward and straps spaced no more than 1/8" wider than the rafter/truss width. Do not install nails where the straps overlap when wrapped over the rafter/truss.

- Straps do not need to be wrapped over the rafter/truss to achieve tabulated loads, unless noted otherwise.

Related Literature

Product Information Table

| Model No. | Ga. | H (in.) | Coating/Material | Packaging Qty. |

|---|---|---|---|---|

| HHETA16 | 14 | 12 | Zinc Galvanized, G90 | 1 |

| HHETA18 | 14 | 14 | Zinc Galvanized, G90 | 1 |

| HHETA20 | 14 | 16 | Zinc Galvanized, G90 | 1 |

| HHETA24 | 14 | 20 | Zinc Galvanized, G90 | 1 |

| HHETA40 | 14 | 36 | Zinc Galvanized, G90 | 1 |

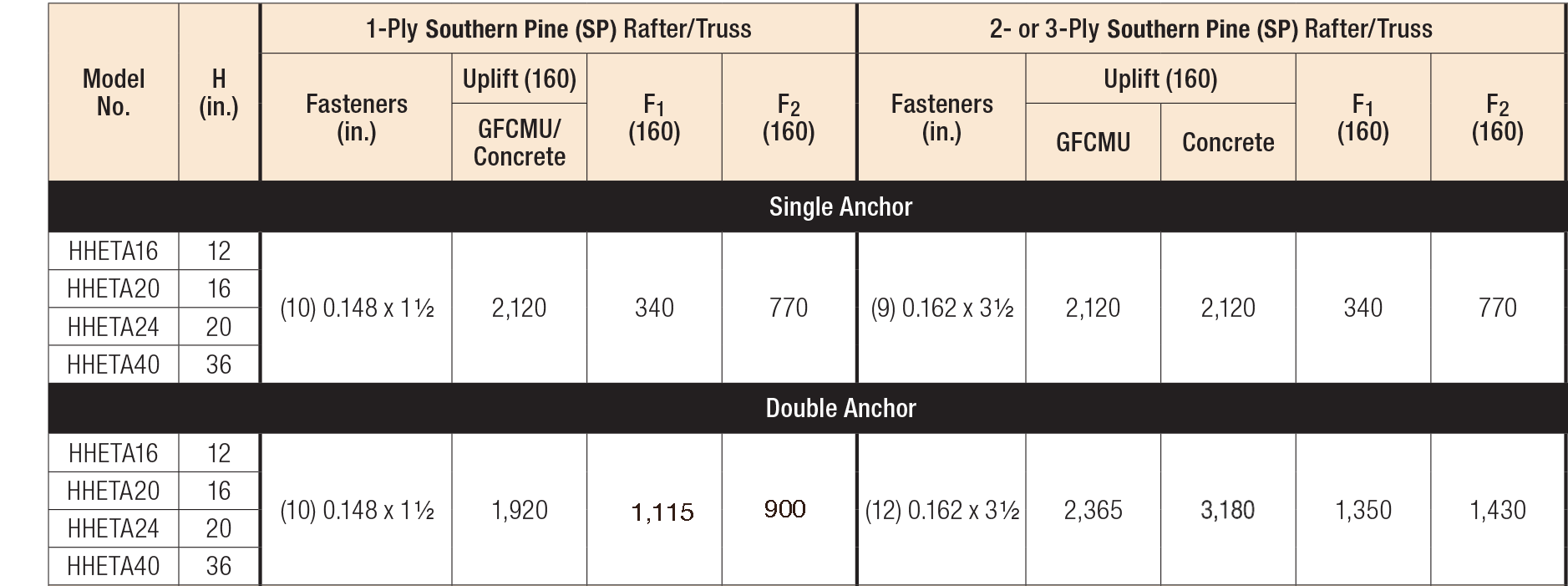

Load Tables

- Loads have been increased for wind or earthquake loading, with no further increase allowed. Reduce where other loads govern.

- Concrete shall have a minimum compressive strength of f'c = 2,500 psi.

- Grout-filled CMU (GFCMU) shall have a minimum compressive strength of f'm = 2,000 psi.

- For simultaneous loads in more than one direction, the connector must be evaluated using either the Unity Equation or the 75% Rule, as described in Straps and Ties General Notes.

- The HHETA allowable F1 load can be increased to 435 lb. if the strap is wrapped over the truss and a minimum of 12 nails are installed.

- F1 lateral loads listed for double HHETA on 2- or 3-ply rafter/truss may cause an additional 1/16" deflection beyond the standard 1/8" limit where the straps are installed not wrapped over the heel as shown.

- Minimum edge distance for HHETA is 1 1/2" for concrete and 2" for masonry. Where edge distance is less than 2" for masonry, the maximum uplift load is 1,005 lb.

- It is acceptable to use a reduced number of fasteners provided that there is a reduction in uplift allowable load. Calculate the connector allowable load for a reduced number of nails as follows: Allowable Load = (No. of Nails Used) / (No. of Nails in Table) x Table Load. Lateral loads require the lowest 7 nail holes filled for HHETA.

- For double HHETA installations, install half of the required fasteners in each strap.

- Fasteners: Nail dimensions in the table are listed diameter by length. For additional information, see Fastener Types and Sizes Specified for Simpson Strong-Tie Connectors.

Code Reports & Compliance

Drawings

| DWG | DXF | RFA | IFC | SAT | |||

|---|---|---|---|---|---|---|---|