HU Heavy Face-Mount Joist Hanger

Face-Mount Masonry Hangers

This product's information may differ depending on the category of use. You are currently viewing details related to Face-Mount Masonry Hangers. You can also view product information related to the categories of: Face-Mount Hangers for Solid Sawn Lumber, Face-Mount Hangers for Engineered Wood, Joist Framing Connectors for Cold-Formed Steel Construction

Product Details

The HU is designed to be installed on a masonry/concrete wall for structures requiring additional strength and safety factors. This heavy-duty, face-mount hanger is available in a variety of sizes to accommodate a wide range of joist sizes.

Key Features

- Available with one flange concealed when the W dimension is less than 2 5/16" at 100% of the table load

- Tested, load rated and code compliant

Material

- 14 gauge (68 mil)

Finish

- Galvanized. Some products available in ZMAX® coating; see Corrosion Information.

Installation

- Attach the hangers to concrete or GFCMU walls using hex-head Titen Turbo screws. Titen Turbo screw anchors for GFCMU (1/4" x 2 1/4" — Model TNT25214H) and for concrete (1/4" x 1 3/4" — Model TNT25134H) are sold separately.

- Drill and prep the holes according to the Installation Instructions provided with the packaging for Titen Turbo screw anchors.

- Caution: Oversized-diameter holes in the base material will reduce or eliminate the mechanical interlock of the threads with the base material and will reduce the anchor’s load capacity.

- Titen Turbo Installation Kits are available (Model TNTINSTALLKIT). A 3/16" x 6" SDS-plus drill bit is also available (Model MDPL01860SH).

- Installation on GFCMU — A minimum edge distance of 1 1/2" and a minimum end distance of 3 7/8" is required as shown in figure 1 for full table loads. For HU models installed with a 5/8" minimum face fastener edge distance, allowable download is 0.63 of table loads with no reduction for uplift loads.

- Installation on concrete — A minimum end and edge distance of 3" is required for full table loads. For edge distances of 1 3/4" minimum and a minimum end distance of 3", the allowable download is 0.90 of table loads with no reduction for uplift loads. For HU models installed with a 5/8" minimum face fastener edge distance, allowable download is 0.63 of table loads with no reduction for uplift loads.

Options

- For both flanges concealed, order HUC

- See table-modifications table for available options and associated load capacities for HU hangers

- For ease of ordering, refer to technical bulletin U/HU Hangers (T-C-U-HU-WS)

Related Literature

Product Information Table

| Model No. | Ga. | W (in.) | H (in.) | B (in.) | Coating/Material | Packaging Qty. |

|---|---|---|---|---|---|---|

| HU1.81/5 | 14 | 1 13/16 | 5 3/8 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU11 | 14 | 1 13/16 | 11 1/16 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU14 | 14 | 1 13/16 | 13 11/16 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU2.1/11 | 14 | 2 1/8 | 11 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU2.1/9 | 14 | 2 1/8 | 9 3/16 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU2.75/10 | 14 | 2 3/4 | 9 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU2.75/12 | 14 | 2 3/4 | 10 3/4 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU2.75/14 | 14 | 2 3/4 | 13 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU210 | 14 | 1 9/16 | 7 1/8 | 2 1/4 | Zinc Galvanized, G90 | 1 |

| HU210-2 | 14 | 3 1/8 | 8 5/8 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU210-3 | 14 | 4 11/16 | 8 1/16 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU210-3Z | 14 | 4 11/16 | 8 1/16 | 2 1/2 | ZMAX® | 1 |

| HU210-4 | 14 | 6 1/8 | 8 3/8 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU210Z | 14 | 1 9/16 | 7 1/8 | 2 1/4 | ZMAX® | 1 |

| HU212 | 14 | 1 9/16 | 9 | 2 1/4 | Zinc Galvanized, G90 | 1 |

| HU212-2 | 14 | 3 1/8 | 10 9/16 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU212-3 | 14 | 4 11/16 | 9 13/16 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU214 | 14 | 1 9/16 | 10 1/8 | 2 1/4 | Zinc Galvanized, G90 | 1 |

| HU214-2 | 14 | 3 1/8 | 12 1/8 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU214-3 | 14 | 4 11/16 | 12 1/16 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU216 | 14 | 1 9/16 | 12 15/16 | 2 1/4 | Zinc Galvanized, G90 | 1 |

| HU216-2 | 14 | 3 1/8 | 13 7/8 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU216-3 | 14 | 4 11/16 | 13 7/8 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU24-2 | 14 | 3 1/8 | 3 1/16 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU26 | 14 | 1 9/16 | 3 1/16 | 2 1/4 | Zinc Galvanized, G90 | 1 |

| HU26-2 | 14 | 3 1/8 | 4 15/16 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU26-3 | 14 | 4 11/16 | 4 5/8 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU28 | 14 | 1 9/16 | 5 1/4 | 2 1/4 | Zinc Galvanized, G90 | 1 |

| HU28-2 | 14 | 3 1/8 | 6 5/16 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU28-4 | 14 | 6 1/8 | 7 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU3.25/10.5 | 14 | 3 1/4 | 10 1/4 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU3.25/12 | 14 | 3 1/4 | 11 3/4 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU3.25/16 | 14 | 3 1/4 | 13 13/16 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU310 | 14 | 2 9/16 | 8 7/8 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU310-2 | 14 | 5 1/8 | 7 13/16 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU312 | 14 | 2 9/16 | 10 7/8 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU312-2 | 14 | 5 1/8 | 10 5/8 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU314 | 14 | 2 9/16 | 12 7/16 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU314-2 | 14 | 5 1/8 | 12 5/8 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU316 | 14 | 2 9/16 | 14 5/13 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU34 | 14 | 2 9/16 | 3 3/8 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU3511 | 14 | 2 3/8 | 10 15/16 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU3514 | 14 | 2 3/8 | 12 1/2 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU3514-2 | 14 | 4 3/4 | 13 1/4 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU3516/22 | 14 | 2 3/8 | 14 1/4 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU3516-2 | 14 | 4 3/4 | 15 1/4 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU3520-2 | 14 | 4 3/4 | 19 1/4 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU3524/30 | 14 | 2 3/8 | 18 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU359 | 14 | 2 3/8 | 9 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU36 | 14 | 2 9/16 | 5 1/4 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU36-2 | 14 | 5 1/8 | 4 3/4 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU38 | 14 | 2 9/16 | 5 5/8 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU38-2 | 14 | 5 1/8 | 5 13/16 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU4.12/11 | 14 | 4 1/8 | 10 5/16 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU4.12/9 | 14 | 4 1/8 | 8 5/8 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU4.28/11 | 14 | 4 9/32 | 11 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU4.28/9 | 14 | 4 9/32 | 9 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU4.75/11 | 14 | 4 3/4 | 11 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU4.75/9 | 14 | 4 3/4 | 9 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU410 | 14 | 3 9/16 | 8 3/8 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU410-2 | 14 | 7 1/8 | 8 9/16 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU410SS | 14 | 3 9/16 | 8 3/8 | 2 1/2 | Stainless Steel | 1 |

| HU410Z | 14 | 3 9/16 | 8 3/8 | 2 1/2 | ZMAX® | 1 |

| HU412 | 14 | 3 9/16 | 10 3/8 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU412-2 | 14 | 7 1/8 | 10 13/16 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU412Z | 14 | 3 9/16 | 10 3/8 | 2 1/2 | ZMAX® | 1 |

| HU414 | 14 | 3 9/16 | 11 15/16 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU414-2 | 14 | 7 1/8 | 12 9/16 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU416 | 14 | 3 9/16 | 13 11/16 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU44 | 14 | 3 9/16 | 2 7/8 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU46 | 14 | 3 9/16 | 4 3/4 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU46SS | 14 | 3 9/16 | 4 3/4 | 2 1/2 | Stainless Steel | 1 |

| HU46Z | 14 | 3 9/16 | 4 3/4 | 2 1/2 | ZMAX® | 1 |

| HU48 | 14 | 3 9/16 | 6 1/8 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU48SS | 14 | 3 9/16 | 6 1/8 | 2 1/2 | Stainless Steel | 1 |

| HU48Z | 14 | 3 9/16 | 6 1/8 | 2 1/2 | ZMAX® | 1 |

| HU5.125/12 | 14 | 5 1/4 | 10 1/4 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU5.125/13.5 | 14 | 5 1/4 | 13 1/4 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU5.125/16 | 14 | 5 1/4 | 13 7/8 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU610 | 14 | 5 1/2 | 7 5/8 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU610Z | 14 | 5 1/2 | 7 5/8 | 2 1/2 | ZMAX® | 1 |

| HU612 | 14 | 5 1/2 | 9 3/8 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU612Z | 14 | 5 1/2 | 9 3/8 | 2 1/2 | ZMAX® | 1 |

| HU614 | 14 | 5 1/2 | 11 5/8 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU616 | 14 | 5 1/2 | 13 3/8 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU66 | 14 | 5 1/2 | 4 3/16 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU68 | 14 | 5 1/2 | 5 13/16 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU68Z | 14 | 5 1/2 | 5 13/16 | 2 1/2 | ZMAX® | 1 |

| HU7 | 14 | 1 13/16 | 6 11/16 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU810 | 14 | 7 1/2 | 8 3/8 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU812 | 14 | 7 1/2 | 10 1/8 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU814 | 14 | 7 1/2 | 11 7/8 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU816 | 14 | 7 1/2 | 13 5/8 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU88 | 14 | 7 1/2 | 6 5/8 | 2 1/2 | Zinc Galvanized, G90 | 1 |

| HU9 | 14 | 1 13/16 | 9 5/16 | 2 1/2 | Zinc Galvanized, G90 | 1 |

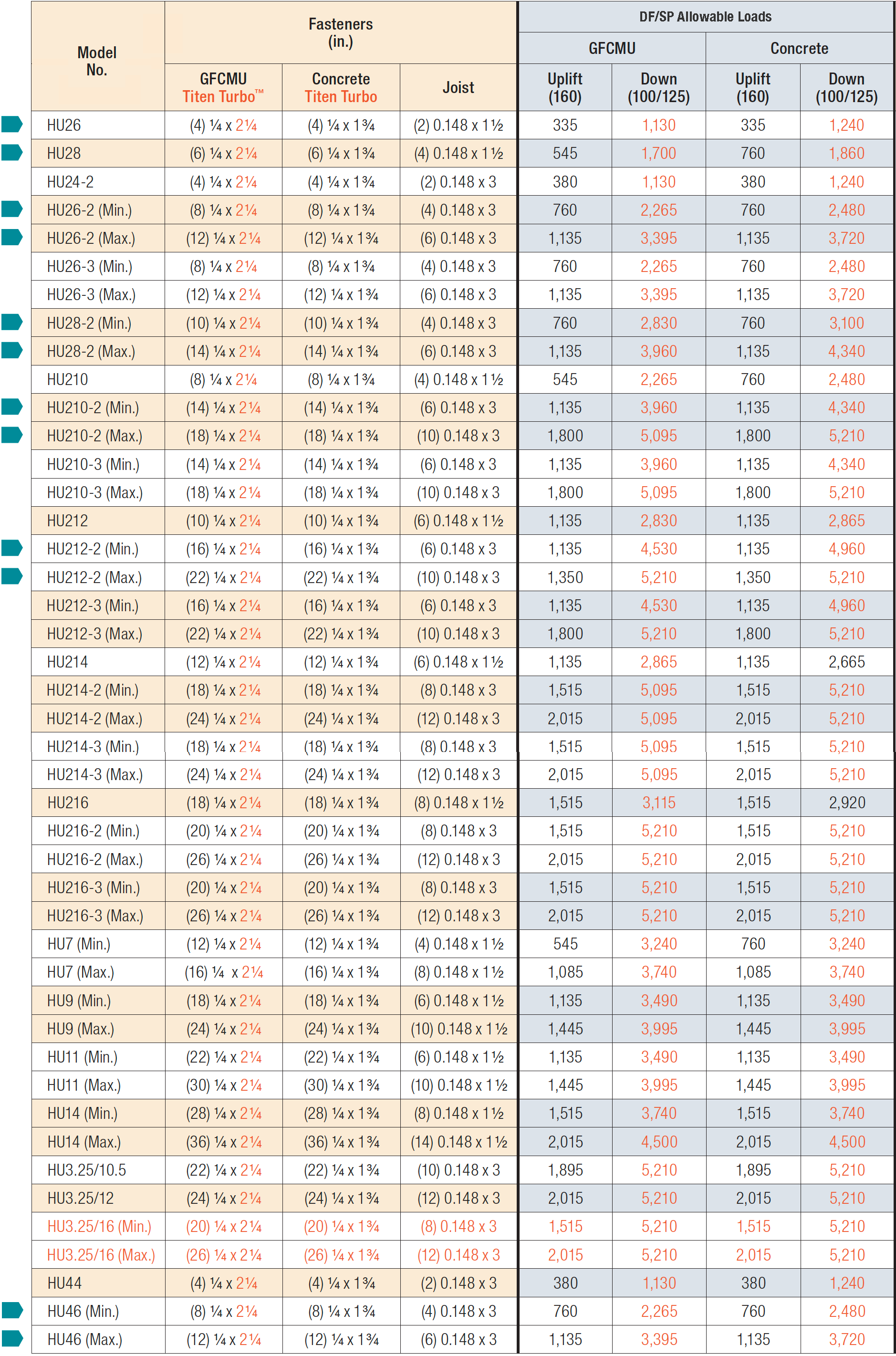

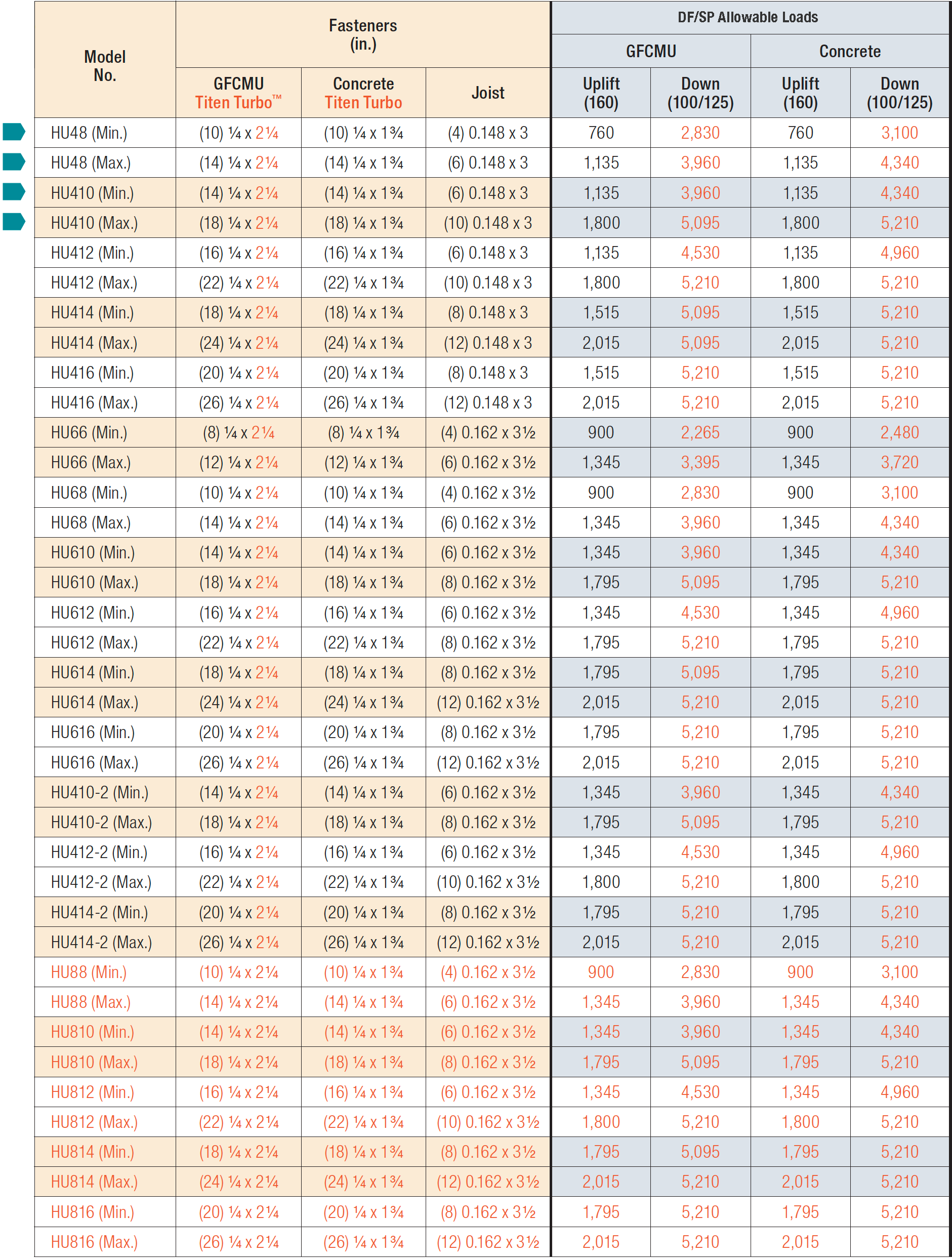

Load Tables

These products are available with additional corrosion protection.

- Uplift loads have been increased for earthquake or wind loading with no further increase allowed. Reduce where other loads govern.

- Concrete shall have a minimum compressive strength of f'c = 2,500 psi.

- Grout-filled CMU (GFCMU) shall have a minimum compressive strength of f'm = 1,500 psi.

- Products shall be installed such that Titen Turbo screws are not exposed to the weather.

- Fasteners: Nail dimensions in the table are diameter by length. Titen Turbo screws are Simpson Strong-Tie concrete and masonry screws (hex-head model required). For additional information, see Fastener Types and Sizes Specified for Simpson Strong-Tie Connectors.

Code Reports & Compliance

Drawings

| DWG | DXF | RFA | IFC | SAT | |||

|---|---|---|---|---|---|---|---|